Crossflow Filtration by PALL

Pall Oenoflow™ XL Filtration System

At the forefront of separation technology

With the introduction of the new generation Oenoflow System, the XL series, wineries are setting new standards in achieving quality, yield and efficiency.

A more compact footprint, reduced waste volumes, and better process control, enable wineries of all sizes to further reduce operating costs whilst maintaining absolute respect for the qualitative characteristics of the wine.

Oenoflow filtration technology replaces traditional diatomaceous earth and sheet filtration in winemaking by using a hollow fiber system that removes suspended contaminants in a single, reliable step.

It clarifies wine without filter aids, centrifugation, or altering the wine’s chemical, physical, or sensory qualities.

The system reduces costs by minimizing wine loss, consumables, and labour, while improving environmental and operator safety through a DE-free, waste-free process.

The new Oenoflow XL systems further enhance efficiency with higher-area modules, better process control, and more compact, economical designs.

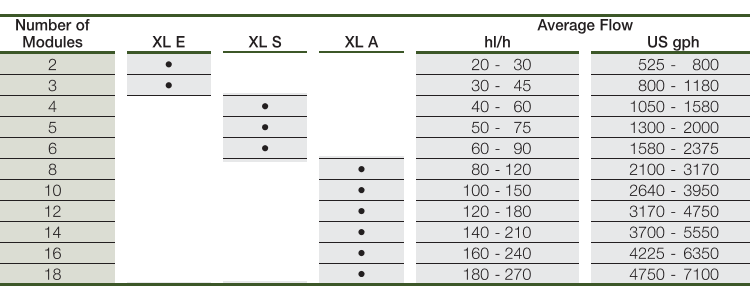

Oenoflow XL Application Range

Whilst the flow rates are strongly influenced by the type of wine, the level of pre-treatment and settling time, the table below provides a guideline for average flow rates considering

6 to 8 hours of continuous operation.Please contact us for assistance to offer the best sized system for your production. Please note this is an average guild only.

eg, An average flow of 100 HL/hr could have a range from 50 HL/hr to 250HL/hr depending on wine variety & pre-treatment.

The right size to fit any production scale

Oenoflow XL – E for small scale operation

- Fully automatic operation capable of combining filtration and cleaning cycles

- On-board process and cleaning tank

- Automatic chemical dosing

- Simple and logical PLC control with touch screen

- Filtrate flow control

- Safety alarms for the product and the system

Oenoflow XL – S for medium to large scale operation

- Fully automatic operation capable of combining filtration, recovery and cleaning cycles

- On-board process and cleaning tank

- Simple and logical PLC control with touch screen

- Automatic chemical dosing

- Small batch filtration program

- High efficiency “solo” water backwash cleanings

- Auxiliary equipment options: remote wine transfer pump, dual pre-filter screens

Oenoflow XL – A for large scale operation

- Fully automatic operation with pre-set and customized working cycles

- On-board process and cleaning tank with incoming wine transfer pump

- Simple and logical PLC control with color touch screen

- Automatic chemical dosing

- Data monitoring and process trend recording

- Automatic Gross Failure Test

- Wide selection of customizable options:

turbidity meter, automatic dual pre-filter screens, LCV , TDS* - eg, Low Concentration Volume, Tank Distribution System