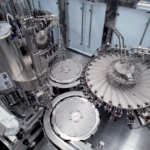

ALFATEK Isobaric bottle filler monoblock

Electropneumatic Isobaric filler – Sparkling wine, beer, water or soft drink

Sizes to suit all production scale – 15 models from 600 bph – 12,000 bph

The isobaric bottling plants of the electropneumatic series today represent the most advanced technological level and production potential achieved by Alfatek in its sector.

The models in this range feature completely innovative technological solutions designed to simplify and optimise the working process based on the isobaric bottling technique.

They are particularly significant among others:

- Patented electro-pneumatically controlled isobaric valve via PLC with touch screen control and dedicated software

- Single or double bottle air pre-evacuation for products sensitive to increased O2 (Beer)

- Pulse final degassing control to allow gradual decompression of the filled bottle reducing foam formation

- Bottle-holding piston anchored at the top, mechanical handling does not require compressed air

- Ring filling tank divided into independent sectors and product introduction into the central holding tank

- Ease of use and significant reduction in annual maintenance costs.

Thanks to these innovations, together with the traditional qualities of robustness, efficiency and comfort, Alfatek’s isobaric systems have achieved a high-quality level recognised at an international level.